We create for each of our customers “Master Execution Plans”, determining the type of coating, appliance, and the adequate surface preparing for each case, achieving this way great durability and efficiency from the used material, according to its use. For this to be accomplished, the next steps need to be followed: :

1. Client’s Needs. We study the need of substrate pretended to be applied.

2. Appliance Procedure. We determine type of system, its components and thickness.

3. Substrate’s preparing. We define the method we have to follow, in base of the required profile by the system, firmness of the substrate and cleanliness.

4. Applying Method. We specify the adequate appliance method for the known materials.

1. Client’s Needs. We study the need of substrate pretended to be applied.

2. Appliance Procedure. We determine type of system, its components and thickness.

3. Substrate’s preparing. We define the method we have to follow, in base of the required profile by the system, firmness of the substrate and cleanliness.

4. Applying Method. We specify the adequate appliance method for the known materials.

Types of Systems

The types of systems which can be applied are:

The types of systems which can be applied are:

Surface Preparings

The correct cleanliness and preparing of the surface, is the first step to ensure the correct functioning of the materials to apply, and it consists in the handing in of a healthy clean and adequate surface. This process includes the elimination of lose concrete and adherence inhibiter film, firmness verifier, porous structure opening, and the establishment of the adequate profile for the appliance system of the specified protective materials.

According to the 03732 International Concrete Repair Institute’s Norm, the required profile depends directly from the thickness of the system to be applied, for which, the presented options may vary the profiles and applied methods. A summary from the relation needed between the thickness of the system, the anchorage profile, and the preparing method of the surface that proportion it, included in the mentioned norm is presented here.

The correct cleanliness and preparing of the surface, is the first step to ensure the correct functioning of the materials to apply, and it consists in the handing in of a healthy clean and adequate surface. This process includes the elimination of lose concrete and adherence inhibiter film, firmness verifier, porous structure opening, and the establishment of the adequate profile for the appliance system of the specified protective materials.

According to the 03732 International Concrete Repair Institute’s Norm, the required profile depends directly from the thickness of the system to be applied, for which, the presented options may vary the profiles and applied methods. A summary from the relation needed between the thickness of the system, the anchorage profile, and the preparing method of the surface that proportion it, included in the mentioned norm is presented here.

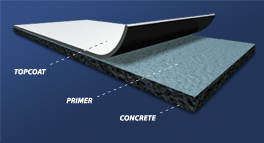

Low and medium thickness coatings

Low and medium thickness Coatings are used in new floors, or in those with very little use to protect them and improve their appearance, they may be applied either by one coat application, or in a layered manner system. When the floor requires extra protection against UV rays, chemical agents, or extreme abrasive conditions, a polyurethane finish may be applied, to achieve these characteristics.

To be applied in: low traffic areas (pedestrian), production areas, warehouses, service and sales area, car shops and garages.

Low and medium thickness Coatings are used in new floors, or in those with very little use to protect them and improve their appearance, they may be applied either by one coat application, or in a layered manner system. When the floor requires extra protection against UV rays, chemical agents, or extreme abrasive conditions, a polyurethane finish may be applied, to achieve these characteristics.

To be applied in: low traffic areas (pedestrian), production areas, warehouses, service and sales area, car shops and garages.

If you need an estimate contact us here.

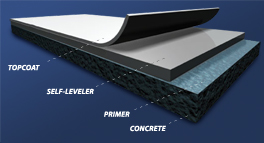

Epoxy self-leveler system

For heavy duty traffic areas or mediumly damaged floor, a self-leveler may be applied as an intermediate layer due to its self-leveling capacity and resistance to abrasion. This system provides a completely smooth finish.

To be applied in: Heavy duty areas (forklifts and vehicles), manufacturing areas, aircraft hangers, loading and unloading areas, clean rooms, and pharmaceutical processes areas.

For heavy duty traffic areas or mediumly damaged floor, a self-leveler may be applied as an intermediate layer due to its self-leveling capacity and resistance to abrasion. This system provides a completely smooth finish.

To be applied in: Heavy duty areas (forklifts and vehicles), manufacturing areas, aircraft hangers, loading and unloading areas, clean rooms, and pharmaceutical processes areas.

If you need an estimate contact us here.

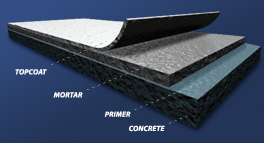

Epoxy repairing system

The surface repairing system is specified for deteriorated areas, or where strong wearing out is expected, due to heavy traffic or impact. The structure formed by epoxy resins and quartz addings, gives the system the capacity to excel in extreme conditions.

To be applied in: loading and unloading platforms, high traffic manufacturing areas, high traffic aisles, production areas, ramps and sanitary cove.

The surface repairing system is specified for deteriorated areas, or where strong wearing out is expected, due to heavy traffic or impact. The structure formed by epoxy resins and quartz addings, gives the system the capacity to excel in extreme conditions.

To be applied in: loading and unloading platforms, high traffic manufacturing areas, high traffic aisles, production areas, ramps and sanitary cove.

If you need an estimate contact us here.

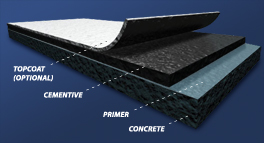

Urethane cementive systems

These are modern cement based systems, modified with urethane resins which provide high performance carpets in extreme weather conditions, and resistance to bacteria growing. Ideal for food or beverage processing plants.

To be applied in: beverage or food processing areas, pharmaceutical industry, make-up manufacturing, industries which need high level hygiene, areas with thermal shock cleaning, warehouses, cold rooms, and ovens.

Acrylic cementive systems

There are systems in the market, capable of leveling and repairing surfaces at a lower cost, with the obvious limitations of an acrylic cement based system, compared to an epoxy based one. This type of system is recommended only for low traffic areas.

These are modern cement based systems, modified with urethane resins which provide high performance carpets in extreme weather conditions, and resistance to bacteria growing. Ideal for food or beverage processing plants.

To be applied in: beverage or food processing areas, pharmaceutical industry, make-up manufacturing, industries which need high level hygiene, areas with thermal shock cleaning, warehouses, cold rooms, and ovens.

Acrylic cementive systems

There are systems in the market, capable of leveling and repairing surfaces at a lower cost, with the obvious limitations of an acrylic cement based system, compared to an epoxy based one. This type of system is recommended only for low traffic areas.

If you need an estimate contact us here.

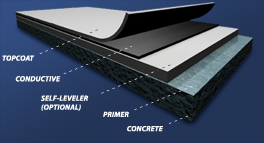

ESD system

This type of system is applied in areas which cannot tolerate electric discharges. It provides a surface capable of dissipating static charges generated by friction. It is possible to combine this type of system with an epoxy self-leveler to obtain extra thickness, and by consequence, better resistance to abrasion.

To be applied in: electronic industry, car assemblage, clean rooms, electronic service areas, surgery rooms, and paint cabins.

This type of system is applied in areas which cannot tolerate electric discharges. It provides a surface capable of dissipating static charges generated by friction. It is possible to combine this type of system with an epoxy self-leveler to obtain extra thickness, and by consequence, better resistance to abrasion.

To be applied in: electronic industry, car assemblage, clean rooms, electronic service areas, surgery rooms, and paint cabins.

If you need an estimate contact us here.

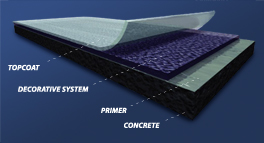

Decorative system

Used when good appearance and durability are required on a floor, see-through epoxy colors systems may be used to obtain the desired requirements.

To be applied in: aisle, school general areas, museums, sport stores, supermarkets, hospitals, kitchens, and food and beverage preparing areas among others.

Used when good appearance and durability are required on a floor, see-through epoxy colors systems may be used to obtain the desired requirements.

To be applied in: aisle, school general areas, museums, sport stores, supermarkets, hospitals, kitchens, and food and beverage preparing areas among others.

If you need an estimate contact us here.

Covertek ©. All Rights Reserved. Total or partial reproduction is prohibited. ©2007 Concept and Development of website: Morfosis ID© Asesores.